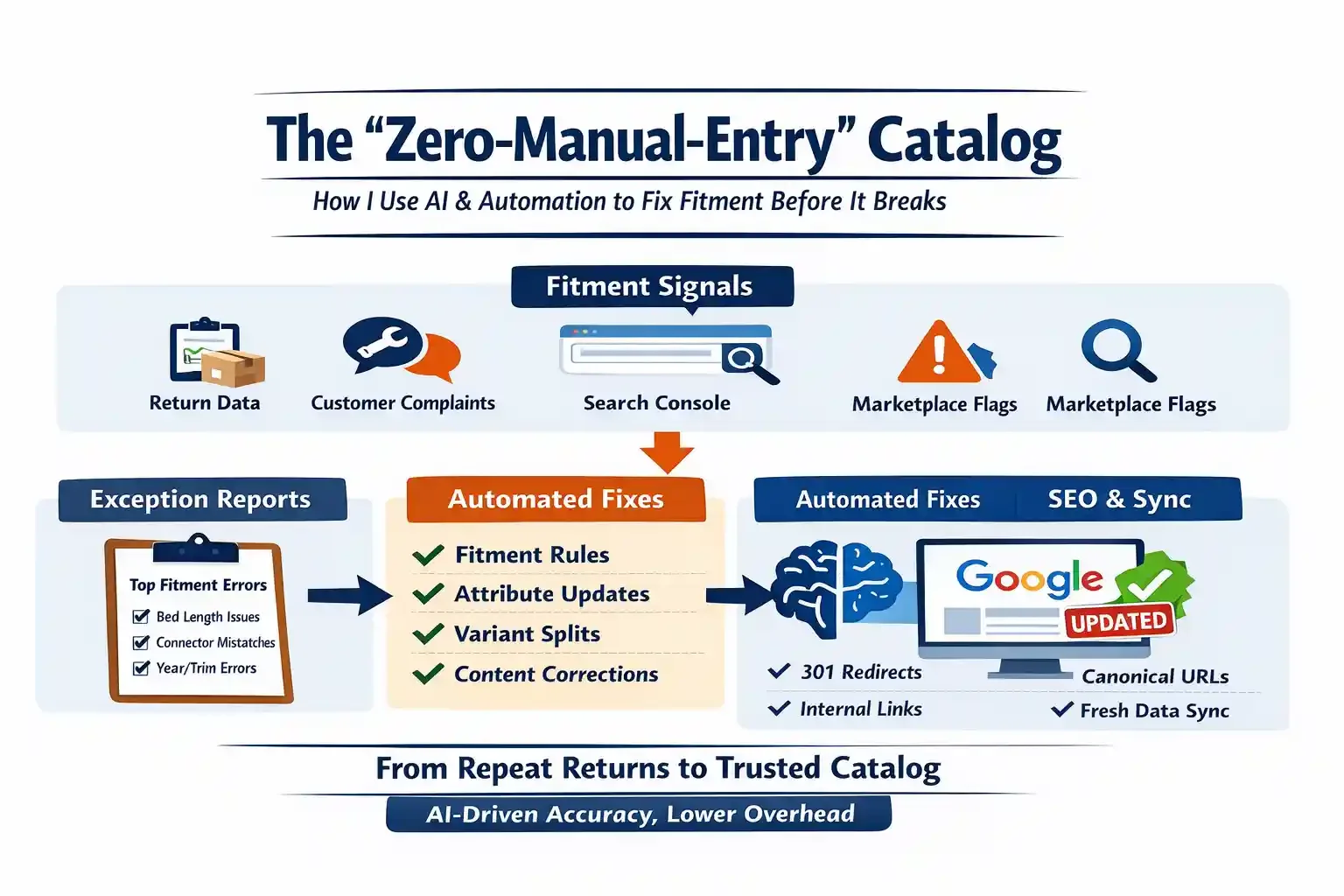

The “Zero-Manual-Entry” Catalog, AI + Automation

How I Use AI + Automation to Catch Fitment Problems Before They Turn Into Returns

Most people hear “automation” and picture robots in a warehouse.

In the aftermarket auto parts world, that’s not the bottleneck.

The real bottleneck is manual entry and manual cleanup - the constant grind of reading returns, scanning customer complaints, chasing broken fitments, updating listings, and then doing it all again next week.

If you sell car parts on eBay Motors, Amazon, Walmart, or your own site (Shopify or Squarespace), you already know the pain:

“Doesn’t fit” returns that nuke margin

Customer service tickets that repeat the same few patterns

Marketplace defects / suppressed listings

A catalog that looks “fine”… until volume exposes the cracks

The fastest way out isn’t a full catalog rebuild.

It’s building a loop that finds the same repeat errors automatically - and pushes them into a clean review queue before they become expensive.

That’s what I mean by a Zero-Manual-Entry Catalog:

Not “no humans involved.”

It means humans stop doing the dumb part - copying, pasting, reformatting, and guessing.

Humans only touch review + decisions.

The uncomfortable truth: catalog audits don’t fail because they’re hard

They fail because they’re never-ending.

A traditional “audit” sounds like a project:

“Let’s audit fitment.”

“Let’s normalize attributes.”

“Let’s clean up SEO.”

But in reality, the catalog is a living thing. It changes every day:

new SKUs

new suppliers

new VCDB updates (or your internal fitment logic)

new marketplace rules

new customer behavior

So a one-time audit becomes death by a thousand cuts. Teams burn out. The work stops. The same issues return.

The solution is not more effort. It’s a system.

The Tech Stack of the Modern Parts Seller (what actually matters)

You don’t need 14 tools. You need a simple stack that creates a feedback loop:

1) Signal Sources (where problems show up first)

Returns reasons (Shopify, eBay, Amazon, internal OMS)

Customer messages (“didn’t fit”, “wrong connector”, “too short”)

Product reviews (especially 1-2 stars)

Search Console queries (Google is literally telling you what users expected)

Marketplace “fitment dispute” or “not as described” flags

2) A “Normalization Layer” (turn messy text into structured data)

This is where LLMs actually shine:

Not to “guess fitment”

But to classify messy human complaints into consistent buckets

3) A Rules + Review Queue (where money gets saved)

A spreadsheet, Airtable, Notion, or a lightweight database table

A workflow that assigns issues to the right owner

A “fix type” + “confidence” score

A “what to change” recommendation

4) Publishing + Propagation (where most teams mess up)

Fixing data isn’t enough. You need to make sure the corrected truth propagates to:

your product page content

your fitment table

your marketplace listings

and Google’s understanding of those pages

That includes SEO hygiene (canonical URLs, redirects, internal links, and freshness signals).

The workflow: how I run it (simple, repeatable, scalable)

Step 1 - Capture return/complaint data automatically

Start with the raw stuff, even if it’s ugly:

Return reason text

Customer message snippets

Order info (SKU, brand, vehicle entered, marketplace/channel)

Date + volume

Goal: one place where every “fitment pain signal” lands.

This can be:

Google Sheet (fine at first)

Airtable (better workflow)

A database (later, if you want scale)

Important: don’t overbuild. Your advantage is speed.

Step 2 - Use AI to normalize complaints into “exception codes”

This is the part that saves the most time.

Humans write complaints like this:

“didnt fit my truck”

“holes don’t line up”

“connector different”

“too short”

“wrong side”

“doesn’t match picture”

That’s not usable for fixing a catalog.

So I convert unstructured text into structured labels, like:

Fitment Error: Year/Model/Trim mismatch

Attribute Error: Bed length / wheelbase

Attribute Error: Engine mismatch

Position Error: Left vs Right

Variant Error: Connector / plug type

Interchange Error: wrong part number mapping

Content Error: photo/description mismatch

Now you have data you can actually trend:

which SKUs produce the most exceptions

which vehicle attributes are missing

which brands/suppliers are repeat offenders

which marketplaces create the most false positives

This is the 80/20 moment.

A small number of repeat patterns usually cause most “doesn’t fit” returns.

Step 3 - Create a ranked exception report (what to fix first)

Don’t fix everything. Fix what’s expensive.

Rank exceptions by:

return rate impact

revenue

ad spend wasted

marketplace penalty risk

customer service time

Your output becomes a weekly “Exception Report” that reads like:

SKU 12345 - 28 returns - “Position Error: Left/Right”

SKU 77881 - 14 returns - “Attribute Error: Bed length”

SKU 99110 - 9 returns - “Variant Error: Connector mismatch”

That report is how you stop playing whack-a-mole.

Step 4 - Apply fixes with rules (not one-off heroics)

Most catalog fixes should be one of these:

A) Fitment rule fix

wrong fitment mapping

missing trims

wrong engine notes

incorrect submodel logic

B) Attribute enrichment

add bed length / wheelbase / door count

connector type

sensor locations

bracket included vs not included

“w/ tow package” or “w/o”

C) Variant separation

one SKU actually needs two options

or a listing needs an explicit selector (plug type, sensor count, etc.)

D) Content correction

photos show the wrong version

bullet points conflict with specs

title implies coverage that isn’t real

The key is to write fixes as repeatable rules:

“Any part with two connector types must be split into two variants.”

“Any application requiring bed length must not be shown without bed length data.”

“Any listing using ‘fits all’ language gets blocked.”

This is where catalog management becomes a system, not an art project.

What this changes in real life

When you run this loop consistently, you get compounding wins:

fewer “doesn’t fit” returns

lower customer service workload

higher conversion (confidence improves)

fewer marketplace defects

a catalog you can scale without hiring an army

And the best part: your time shifts from cleanup to growth.

That’s when you can actually do the work that moves the business:

expand SKU coverage

improve marketplace readiness

build private label correctly

invest in better content

If you’re trying to build this and don’t know where to start

Start small:

Pick one channel (eBay Motors or your site)

Pull 30 days of returns + messages

Normalize into exception codes

Rank by impact

Fix the top 10 issues

Repeat weekly

That alone will beat the “we’ll audit later” teams by miles.

If you want help building the workflow (exception taxonomy, automation design, catalog rules, marketplace propagation, and SEO structure), that’s exactly what I do at Parts Advisory - practical catalog + fitment + marketplace consulting focused on returns reduction and scalable growth.

Want a repeatable “Exception Report” for your catalog? Send me 30 days of anonymized returns + customer messages and I’ll show you the top failure patterns and the fastest fixes.