MPN Normalization for Auto Parts

Reduce Duplicate SKUs and Improve Search

If your catalog has duplicate SKUs, you do not just have a messy spreadsheet. You have a revenue leak.

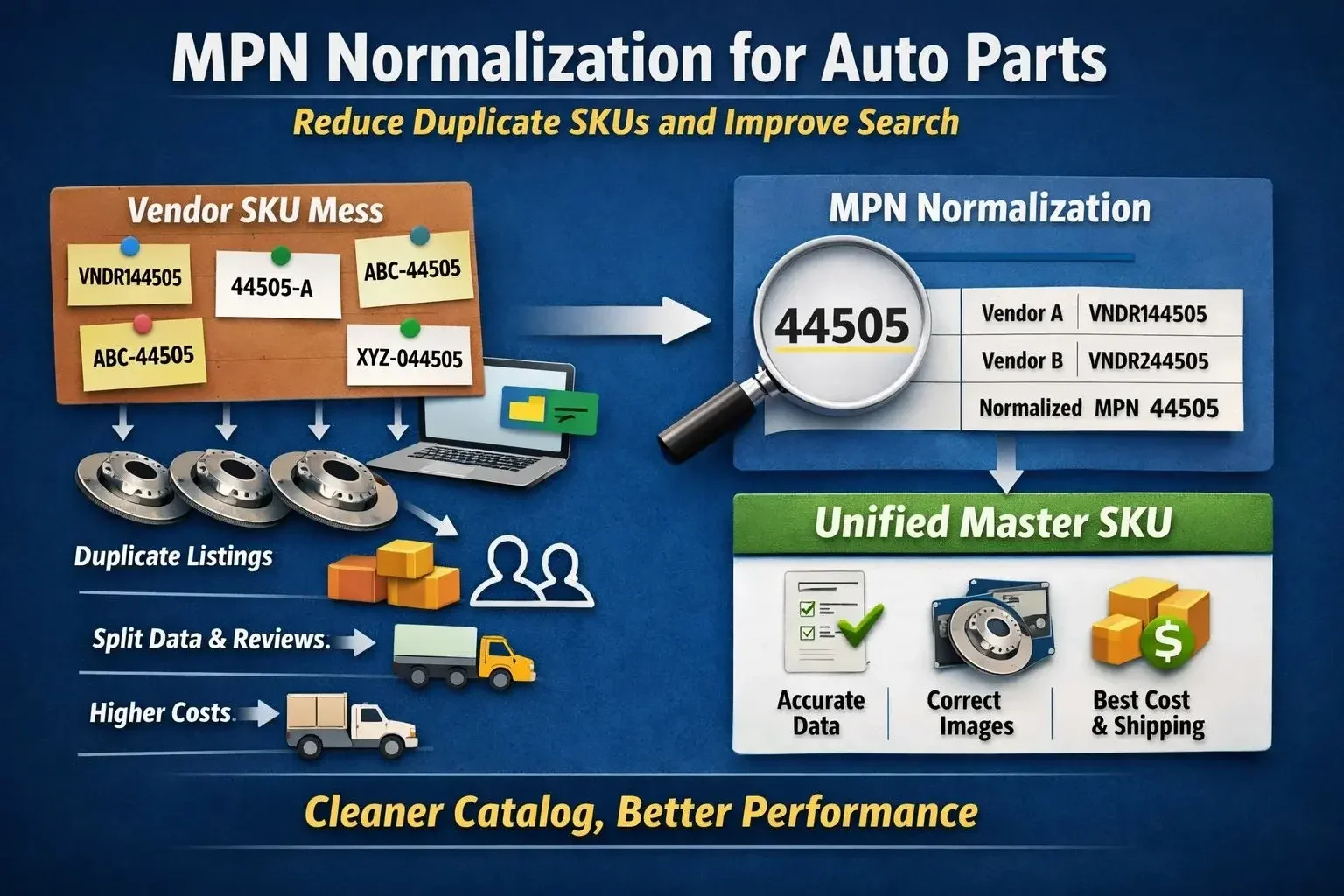

In auto parts, the same part number is often represented five different ways. A dash here. A space there. Leading zeros. Mixed case. A suffix added by a distributor. Another suffix added by a seller. Then someone exports it to a marketplace feed and the formatting changes again.

To a human, it is the same part.

To Amazon, eBay, Walmart, and your own internal systems, it can become five different products.

That is how you end up with duplicate listings, split reviews, split sales history, suppressed visibility, and returns that look random but are actually predictable.

MPN normalization is the unsexy fix that makes everything else work better.

What MPN normalization actually means

MPN normalization is creating a consistent, machine readable version of the manufacturer part number so the same part is represented the same way across your catalog, your feeds, and your marketplace listings.

You are not inventing a new part number. You are separating vendor item numbers from the true MPN, then standardizing how the MPN is represented everywhere.

Think of it like this:

Raw MPN is whatever came from a file, a vendor, or a legacy system

Normalized MPN is the version your catalog uses consistently

Vendor item numbers are the identifiers vendors create for their own systems

Your master SKU is the single internal key you use to attach content and supply options

When you do this well, duplicates collapse, search improves, and buyers get less confused.

Vendor prefixes are not MPNs and they quietly break everything

One of the most common catalog mistakes I see is treating a vendor’s SKU as the manufacturer part number.

Vendors frequently add prefixes and suffixes for their own internal system. That does not mean it is the MPN.

Example:

True MPN: 44505

Vendor A sends: VNDR144505

Vendor B sends: VNDR244505

Your legacy system might also contain: 44505

To a human, those are obviously the same part. To a catalog system, they often become three different SKUs, three different listings, and three different products.

This is where duplicate SKUs are born.

Why this matters beyond duplicate cleanup

If you correctly understand and normalize vendor prefixes and suffixes, you unlock two real advantages.

First, you can map the same part across multiple vendors and buy smarter.

Once you know that VNDR144505 and VNDR244505 both resolve to MPN 44505, you can source the part from whichever vendor has the best landed cost and service level for that day.

Here is what that looks like in practice:

Vendor A cost is $18.20 and ships from California with one day ground.

Vendor B cost is $16.90 and ships from New Jersey with three day ground.

Your customer is in Los Angeles.

The cheapest part is not always the best deal. The best deal is the lowest landed cost that still meets your delivery promise, including shipping cost, zones, and handling.

You cannot do this if your system thinks those are different parts.

Second, you stop the content mismatch nightmare.

This gets worse when you pull product data from one source and fitment, images, or titles from another.

Example:

Vendor A provides pricing and inventory as VNDR144505

A data provider provides images and applications under 44505

Vendor B provides attributes under VNDR244505

If your catalog cannot match those identifiers together, your data becomes fragmented:

pricing lives on one SKU

images live on another SKU

fitment lives on a third SKU

That is how you get listings with the right price but no image, or the right image but wrong fitment, or the right part but the wrong buyer expectation. It looks like chaos, but it is usually just an identifier mapping failure.

The fix is a crosswalk, not a guess

You need a clean model:

Vendor item number is what the vendor calls it

MPN is the true manufacturer part number

Brand is required to prevent collisions

Master SKU is your internal product key

A simple crosswalk solves this:

Vendor A item number VNDR144505 maps to ExampleBrand and raw MPN 44505.

Vendor B item number VNDR244505 maps to ExampleBrand and raw MPN 44505.

Both normalize to the same normalized MPN 44505.

Both roll up to one master SKU, for example EXAMPLEBRAND 44505.

Now you can attach all content to the master SKU and treat vendors as supply options for the same product.

Why duplicate MPNs create real damage

Duplicate MPNs do not just bloat your catalog. They break performance.

Here is what they cause in the real world:

Duplicate listings across marketplaces that compete with each other

Split conversion signals, so none of the listings look strong

Split reviews and Q and A, so trust builds slowly

Bad item specifics matching, because attributes attach to one version but not the other

Higher returns, because buyers cannot tell what is truly the same part

Forecasting noise, because demand is split across multiple SKUs that should be one

This is why teams feel like they are doing everything but results stay flat. The foundation is leaking.

The 80 20: 10 normalization rules that solve most cases

There is no perfect universal rule set because every brand has quirks. But you can solve the majority of duplicates with a disciplined baseline.

Trim whitespace. Remove leading and trailing spaces. Collapse double spaces.

Standardize case. Convert to uppercase. Keep it consistent everywhere.

Remove hidden characters. Tabs and non printing characters break matching.

Normalize separators. Decide a policy for dashes and spaces and apply it consistently.

Define a leading zero policy. Some brands use meaningful leading zeros. Some do not. Use an exception list.

Strip formatting noise. Periods, slashes, and random punctuation often show up from legacy systems.

Handle suffixes intentionally. Suffixes like R, REV, KIT, and HD can be meaningful or garbage. Do not guess. Control them.

Use a brand prefix policy when needed. If collisions happen, treat Brand plus MPN as the key.

Reject placeholders. Kill junk like N A, UNKNOWN, SEE NOTES.

Create an exception list on day one. Exceptions are not failure. They are reality.

The collision problem you must catch

Normalization can collapse two different raw MPNs into one normalized value. Sometimes that is correct. Sometimes it is a disaster.

Example: 01234 and 1234 might be the same, or they might be two different parts in a brand’s system.

That is why every normalization pipeline needs collision detection.

If two raw MPNs normalize to the same value and the brand or core product attributes differ, flag it for review.

This one control prevents a lot of silent catalog corruption.

The part nobody warns you about

In my experience, this is hard at the start.

You do not set one global rule and call it done. You end up building rule logic by brand and by source.

Some sources add prefixes by brand. Some add prefixes by category. Some add prefixes based on product series or internal routing. The same brand can look different depending on which vendor or file it came from.

So the early phase feels messy. You build rules. You find exceptions. You tighten. You break a few things. You fix them. You tighten again.

But once your rules mature, the payoff is huge.

You start living in a cleaner, duplicate free environment where supply, content, and fitment can finally connect to the same product. Everything downstream gets simpler.

How to implement MPN normalization without breaking your catalog

Do not do this as a big bang project. Do it like an operator.

Step one: start with the money. Pull your top revenue SKUs or your top traffic SKUs.

Step two: build a mapping table. Raw to normalized. Vendor item number to MPN. Brand included.

Step three: add collision detection so merges are reviewed.

Step four: apply normalization in your internal catalog first. Your feeds should pull from clean values.

Step five: roll out marketplace by marketplace and measure impact.

What changes on marketplaces when MPNs are clean

On Amazon, cleaner identifiers reduce duplicate product pages, stabilize variation logic, and improve attribute matching.

On eBay Motors, consistent identifiers improve item specifics consistency and reduce duplicate listings. Buyer confidence improves because the listing set looks coherent.

On Walmart, normalization improves match quality and reduces duplicate catalog objects.

Across all channels, the win compounds. When the catalog becomes consistent, merchandising work starts to stick.

The metrics that tell you it is working

Track these before and after:

Duplicate SKU count per brand

Sessions and impressions per normalized MPN group

Conversion rate on merged listings

Return rate, especially ordered wrong part and does not fit

Suppression or quality flags tied to identifier issues

If duplicates drop and conversion rises, you are watching the leak close.

Final thought

MPN normalization is not a data hygiene project. It is a marketplace performance project.

Marketplaces reward consistency. They punish fragmentation.

If your catalog represents one part as many, you are forcing every downstream system to guess. Buyers guess too. Returns follow.

Want help applying this to your catalog

If you want a fast, practical way to find and fix duplicates, I offer a free Catalog Health Review focused on duplicate drivers, MPN hygiene, fitment risk, and marketplace suppression triggers.

Contact PartsAdvisory and I will share next steps.