Cross-Selling Auto Parts

Bundles, Kits, and Smarter Cart Decisions That Actually Work

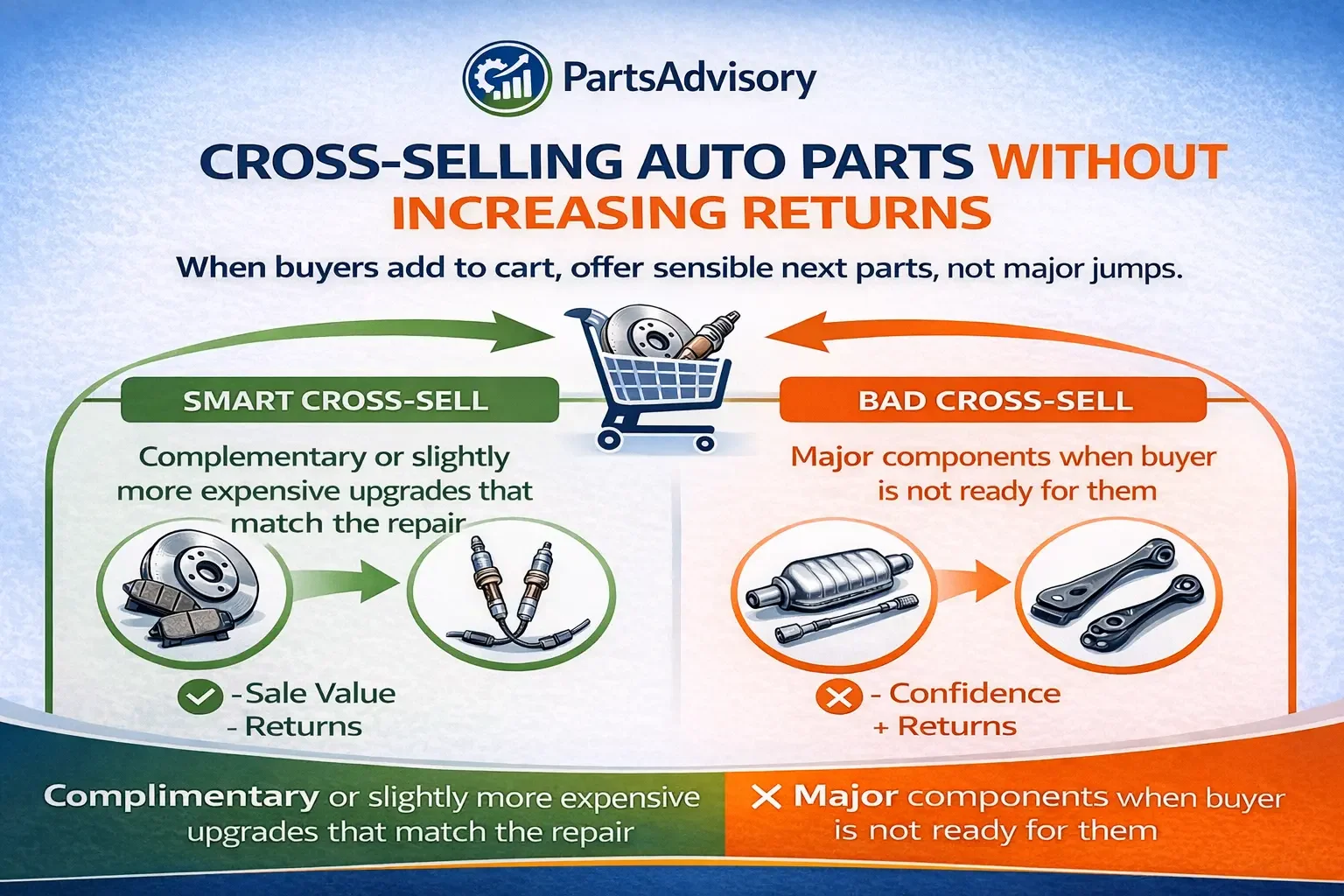

Cross-selling in auto parts is not about selling more items.

It is about selling the right next item at the right moment.

Most cross-sell programs fail because they are copied from general ecommerce playbooks. In auto parts, the wrong recommendation does not just reduce conversion. It creates returns, cancellations, negative feedback, and long-term trust issues.

I have seen cross-sell work extremely well when it follows repair logic, fitment discipline, and buyer intent. I have also seen it quietly destroy margin when it ignores those rules.

This article explains how to cross-sell auto parts across marketplaces and ecommerce sites without increasing returns, based on real-world operator experience.

Why cross-selling fails in auto parts

In apparel, a bad cross-sell is harmless.

In auto parts, it is expensive.

Common failure patterns look like this:

recommending parts that do not match the repair being done

pushing expensive upgrades too early in the decision

offering add-ons that introduce fitment ambiguity

treating cross-sell like a marketing tactic instead of a catalog and operations problem

When this happens, buyers guess. Guessing leads to wrong orders. Wrong orders lead to returns. Returns hurt visibility, metrics, and profitability.

The goal of cross-sell in auto parts is not higher cart value at any cost.

The goal is higher cart value with equal or lower return rates.

The two types of cross-sell that actually work

1) Same-job cross-sell

These are parts that are replaced together during the same repair. This is the safest and highest-performing cross-sell category.

Examples:

brake pads with rotors

struts with mounts

control arms with sway bar links

ignition coils with spark plugs

radiator with hoses and coolant

wheel hubs with axle nuts or hardware kits

Same-job cross-sells work because they reduce repeat labor and incomplete repairs. They also reduce the chance of a second order later.

2) Preventive add-on cross-sell

These are parts that reduce future failure or improve longevity. They work best when fitment is simple and the value is obvious.

Examples:

serpentine belt with tensioner

thermostat with coolant

cabin air filter with disinfectant spray

wiper blades with washer fluid

Preventive add-ons should never create a second decision tree. If the buyer has to think too hard, conversion drops and returns increase.

Direction matters more than relationship

One of the most important lessons we learned is that cross-sell is directional.

Just because two parts are related does not mean you should recommend them both ways.

Example: catalytic converters and oxygen sensors

When a customer is shopping for a catalytic converter, they are already committed to a major repair. In that moment, offering oxygen sensors makes sense. It is a common do-it-once job and the incremental cost feels reasonable compared to the total repair.

But the reverse does not work.

If a customer is shopping for a single oxygen sensor, they are usually troubleshooting a check engine light. They are not ready to jump to a catalytic converter. Offering one at that moment often reduces confidence and hurts conversion.

The correct cross-sell when someone buys an oxygen sensor is:

the correct upstream or downstream sensor

related hardware if applicable

simple install items when relevant

Big repairs can suggest smaller related items.

Small diagnostic purchases should not escalate into major replacements.

Example: ball joints and control arms

Ball joints are another common trap.

If a customer is buying a ball joint, they are usually replacing one side. The best cross-sell is the matching left or right ball joint, or the opposite side if they are doing both.

Control arms can be a great offer when the customer is already shopping for control arms, especially if the upgraded version includes ball joints or bushings.

But offering a full control arm to someone buying a single ball joint often feels unnecessary and lowers conversion.

When we aligned cross-sell direction with repair logic, attach rate increased and returns stayed flat. When we ignored direction, performance suffered.

The fitment gate rule that prevents most returns

Here is the rule we lived by:

If a shopper can choose the wrong version without noticing, the cross-sell must be gated or explained clearly.

This applies to parts with:

left and right sides

front and rear positions

engine or drivetrain variations

trim or towing package differences

different connector types

Cross-sell should remove uncertainty, not add another way to make a mistake.

Bundles are not a merchandising idea

You can create a bundle listing quickly.

You cannot scale bundles without operational support.

True bundles require:

component-level inventory logic

pick and pack workflows that treat the set as one unit

clear rules for partial returns and damage claims

policies for orphan components

Without this, bundles eventually break under volume.

The safer path for most teams is to start with virtual kits and graduate to physical bundles only when systems and processes are ready.

The cart moment is where ecommerce sites win

Marketplaces have limits. Your own ecommerce site has an advantage.

When a customer adds an item to cart, intent is high. This is the moment to provide clarity, not pressure.

There are three cart offers that work extremely well when done correctly.

Offer a cheaper option that still fits

Sometimes the buyer is price constrained. Offering a validated lower-cost option can reduce abandonment.

Examples:

standard brake pads versus premium pads

non-heated mirror versus heated mirror

basic wiper blades versus premium beam blades

The key is transparency. The buyer should understand exactly what changes and what stays the same.

Offer a slightly higher-cost option that changes the value equation

This is the most profitable and least risky cross-sell when done right.

Examples:

control arm upgrade that includes two ball joints for a small price difference

brake kit that includes hardware clips

strut assembly that includes mount and spring

wheel hub that includes the ABS sensor

headlight sold as a matched pair

These upgrades work because the math is simple. A small increase buys less labor, fewer surprises, and lower risk.

Offer a complete repair kit

Incomplete repairs drive returns and second orders.

Examples:

brake pads, rotors, and hardware

spark plugs, coils, and grease

suspension components with hardware kits

radiator with hoses and coolant

Always show what is included clearly, ideally with a single image.

The cross-sell ladder you should follow

Not every cross-sell needs a physical bundle SKU.

Level 1: frequently bought together

Level 2: virtual kits

Level 3: true bundle SKUs

Most teams should spend much more time at levels one and two than they think.

The two metrics that must be tracked together

Never track attach rate alone.

Track:

attach rate or AOV lift

return rate and defect rate on the combined order

If attach rate goes up and returns increase, the cross-sell did not create value.

A practical way to start this week

If you want a fast, low-risk win:

pick 20 high-volume SKUs with stable supply

map the top two same-job add-ons for each

add one clear fitment notes bullet

add one what’s-included image for kits

add one upgrade offer with obvious value

measure attach rate and returns together

This is how you build cross-sell that scales.

Want help building a cross-sell engine that does not create returns

If you send me your top categories and top SKUs, I can map:

the best same-job and directional cross-sells

which offers should be virtual kits versus true bundles

the fitment gates needed to protect conversion

and the cart structure that raises AOV without increasing returns

Contact PartsAdvisory and I will share next steps.